The Issues at Hand

Strawberries in America are a multi billion dollar industry. Virtually all strawberries grown in the US are grown as annuals. To guarantee optimal production, every season strawberry plants are replaced with new annual transplants.

However, the strawberry industry is facing a multitude of challenges that are related to the production, distribution and quality of those annual transplants

1. Strawberry transplants can be symptomless carrier of diseases

Strawberry transplants delivered to growers can show diseases later in a fruit production field. Species of Collectotrichum acutatum and C. gloeosporioides (Disease: Anthracnose) could be traced back to nurseries in more than 150 cases over the past decade in North Carolina, Florida and California’s south coast. Other pathogens such as Botrytis cinerea (Disease: gray-mold), Xanthomonas fragariae (Disease: angular leaf spot) or Podosphaera phanis (Disease: Powdery mildew) are frequently associated with transplants. New diseases such as Neo-Pestalotiopsis fruit rot are frequently transported through transplants into fruiting fields as well, causing significant damages on some farms.

2. Methyl Bromide (MB) Dependency

Open-field strawberry nurseries in the US and Canada depend on MB as soil fumigant to reduce nematode and disease pressure on planting stock. Without MB, the risk to introduce soil-borne nematode, nematode-transmitted viruses and soil-borne pathogens such as Phytophthora ssp., Pythium ssp., and Rhizoctonia spp. root rot, Fusarium oxysporum or Macrophomina phaseolina increases significantly. This would add tremendously to costs of operation, requiring thorough screening of billions of transplants every year.

This problem is exacerbated by stricter regulatory changes, requiring the use of less effective fumigants and higher costs for fumigant applications. Strawberry nursery operations in the US rely currently on critical use exemptions for a MB:Clorpicrin mix as pre-plant soil disinfectant. Looming stricter regulations would make it more difficult for the nursery industry to produce pathogen free transplants, increasing the vulnerability of the current American strawberry farming industry dramatically.

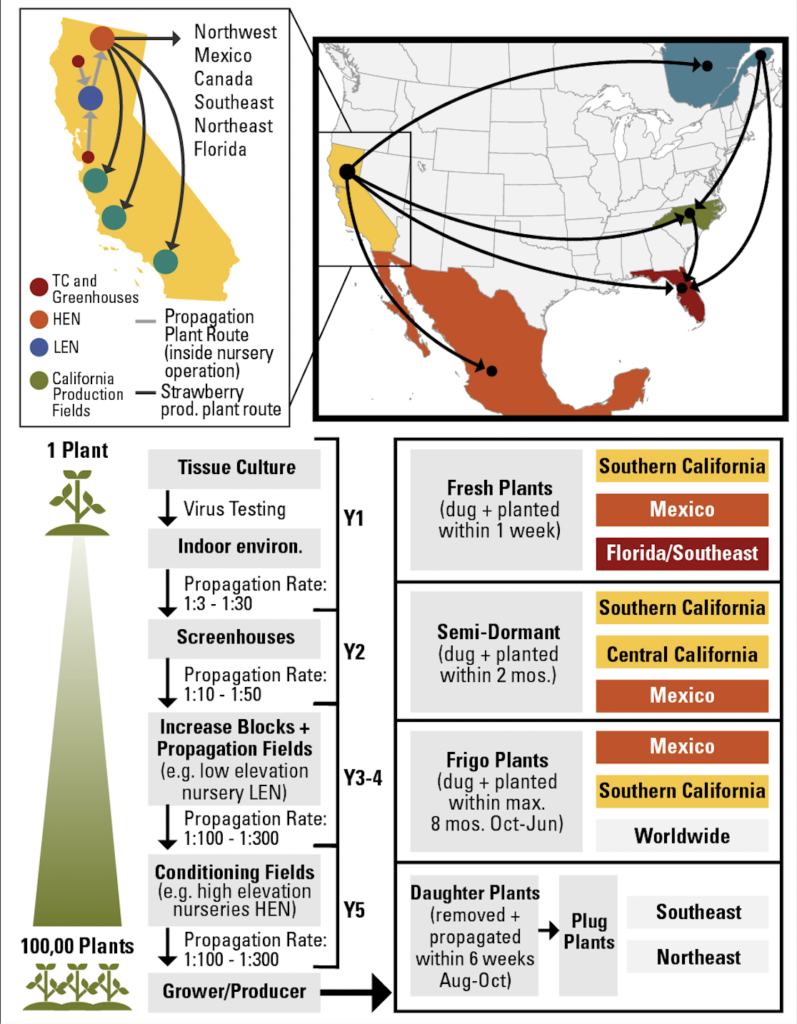

3. Strawberry transplant production is a multi-year and multi-location operation

Strawberry transplant production is highly cost-intensive and labor intensive, requiring high up-front investment, recurring new investment into technology, as well as high maintenance cost and for labor. Open-field locations are threatened by droughts, run-off, floods, wildfires. Increasing costs for labor, labor shortages in often remote areas, increased transportation costs, higher fixed costs for duplicative infrastructure and equipment are a drain on the current strawberry transplant producers.

CONCLUSION

Because of the above mentioned challenges, we work together with industry to develop alternative strawberry propagation and transplant production solutions that do not require the use of MB and minimize the possibility of disease spread. We specifically work in Controlled Environments to optimize strawberry propagation and fruit production of resulting transplants, and test those solutions in the field and with industry partners.

This work is supported by Specialty Crop Research Initiative (SCRI), Grant no. 2021-51181-35857, Project accession no. 1027418, sponsored by the USDA National Institute of Food and Agriculture. Please use this link for more information.